The importance of proper LED Industrial Lighting in large-scale environments

When managing large facilities such as warehouses, manufacturing plants, or logistics centers, the role of LED Industrial Lighting cannot be underestimated. Lighting is not just about visibility, it directly affects productivity, energy efficiency, and workplace safety. Employees need an environment where they can work with precision, where shadows do not compromise accuracy, and where fatigue is minimized by stable, high-quality illumination. This is where LED Industrial Lighting plays a transformative role. It provides clear, uniform brightness across vast areas while significantly reducing operational costs compared to traditional lighting technologies. By adopting LED Industrial Lighting, facilities benefit from long lifespans, minimal maintenance, and energy savings that make a measurable difference on annual budgets.

Proper lighting selection is not just a technical decision but also a strategic investment in efficiency and workforce well-being. Facilities that choose the right LED Industrial Lighting setup enjoy enhanced safety, improved workflow, and sustainable practices that support corporate responsibility goals. With more industries moving toward automation, precision, and energy efficiency, selecting the correct lighting solution is crucial for maintaining competitiveness in today’s market.

Factors to consider when selecting LED Industrial Lighting

Assessing the size and layout of the facility

Large facilities vary greatly in design, from open-floor warehouses to multi-level manufacturing environments. The size and structure of the space directly determine the type and placement of LED Industrial Lighting. High-ceiling areas may require high bay lights for broad and powerful illumination, while task-specific zones might benefit from focused fixtures. Understanding the dimensions and layout ensures lighting is distributed evenly without dark corners or wasted energy.

Evaluating energy efficiency and cost savings

One of the primary reasons facilities shift to LED Industrial Lighting is energy efficiency. Compared to conventional lighting, LED systems consume significantly less power while delivering brighter and more consistent light output. In facilities operating 24/7, the cumulative savings are substantial. Lower energy use not only reduces costs but also supports sustainability targets. Additionally, reduced heat emission from LEDs decreases the strain on cooling systems, further improving energy performance.

Design considerations for LED Industrial Lighting

Light distribution and beam angles

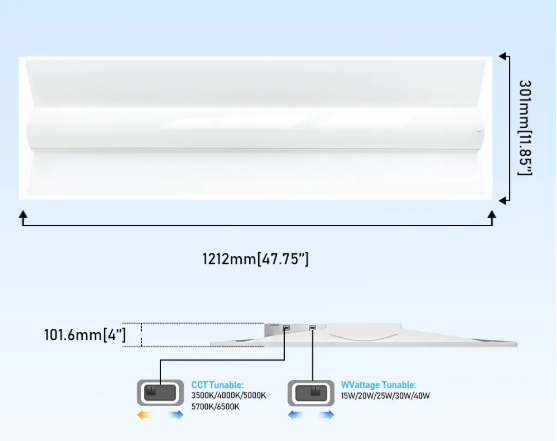

Uniform light distribution ensures that workers across all areas of the facility have consistent visibility. LED Industrial Lighting offers customizable beam angles, allowing managers to tailor lighting to specific zones. Wide beam angles may suit open storage areas, while narrower beams can target assembly lines or inspection stations. This flexibility helps in achieving operational precision and reducing visual fatigue.

Color temperature and brightness levels

Choosing the right color temperature is another crucial factor. Cooler color temperatures promote alertness and focus, making them ideal for production environments. Warmer tones may be more suitable for rest areas within the facility. Adjusting brightness levels is also essential, as overly harsh lighting can cause glare, while insufficient lighting can increase risks of accidents. With LED Industrial Lighting, brightness can be fine-tuned to create the perfect balance.

Installation and maintenance of LED Industrial Lighting

Planning proper installation for maximum efficiency

Even the best lighting systems can underperform if installed incorrectly. Installation planning should take into account ceiling height, machinery placement, and traffic flow. Professional installation ensures that LED Industrial Lighting provides full coverage and that fixtures are positioned for both function and safety. A poorly planned setup can create shadows, blind spots, or unnecessary light overlap.

Ensuring long-term maintenance and reliability

LED Industrial Lighting is known for its durability and longevity, but maintenance cannot be ignored. Dust and debris in industrial facilities can accumulate on fixtures, reducing light output. Routine cleaning, inspection of fittings, and timely replacement of components like drivers help preserve performance. A proactive maintenance plan ensures lighting systems remain reliable over the years with minimal disruption to operations.

Benefits of LED Industrial Lighting for large facilities

Enhanced workplace safety and visibility

In large facilities, safety is a top priority. Poor lighting can increase the risk of accidents, from slips and falls to machinery errors. LED Industrial Lighting reduces these risks by providing clear, consistent visibility. Workers can identify hazards more quickly, machinery can be operated with precision, and overall safety compliance improves.

Productivity and employee well-being

The impact of lighting on productivity is often underestimated. Proper LED Industrial Lighting reduces eye strain, supports focus, and minimizes fatigue. Employees working in well-lit environments demonstrate higher accuracy and efficiency. In the long run, this contributes not only to better performance but also to employee satisfaction and retention.

Technology advancements in LED Industrial Lighting

Smart control systems and automation

Modern LED Industrial Lighting is no longer static. Integration with smart controls allows facilities to adjust lighting based on occupancy, daylight availability, or production schedules. Automated dimming and zoning systems reduce unnecessary energy consumption while maintaining optimal lighting conditions. This adaptability enhances both efficiency and sustainability.

Integration with energy management systems

LED Industrial Lighting can also be integrated with broader energy management systems, allowing facility managers to monitor consumption, adjust strategies, and analyze performance in real-time. This data-driven approach ensures maximum savings and supports long-term environmental goals.

Cost considerations of LED Industrial Lighting

Initial investment versus long-term savings

The upfront cost of LED Industrial Lighting may seem higher than traditional alternatives, but the return on investment is significant. Reduced energy bills, lower maintenance needs, and extended fixture lifespan combine to deliver cost savings over time. Facilities often recoup their investment within just a few years of installation.

Financing options and incentives

Governments and energy organizations in many regions offer incentives, rebates, or tax benefits for adopting energy-efficient technologies. Facilities investing in LED Industrial Lighting may qualify for these programs, further reducing the total cost of ownership. Exploring financing options ensures companies can adopt advanced lighting without straining budgets.

Customization and adaptability of LED Industrial Lighting

Tailoring lighting solutions to facility operations

No two facilities are identical. Customizing LED Industrial Lighting ensures that the system supports specific operational needs. For example, storage facilities may prioritize wide coverage, while assembly lines require concentrated illumination. Custom solutions guarantee that each area of the facility receives optimal lighting.

Future-proofing with scalable designs

Industrial needs evolve over time, and lighting should evolve with them. Scalable LED Industrial Lighting systems allow facilities to expand or adjust their setups as operations grow. This adaptability ensures that the investment remains relevant and effective for years to come, without the need for costly replacements.

Sustainability and environmental impact of LED Industrial Lighting

Reducing carbon footprint and energy consumption

One of the biggest advantages of LED Industrial Lighting is its contribution to sustainability. Lower energy consumption directly translates to reduced carbon emissions. Facilities that adopt LED solutions take measurable steps toward greener operations and demonstrate commitment to environmental responsibility.

Compliance with environmental regulations

Many industries are subject to strict environmental regulations. LED Industrial Lighting helps facilities remain compliant by reducing waste, limiting hazardous materials, and minimizing overall environmental impact. This compliance not only avoids penalties but also enhances brand reputation.

FAQ

What makes LED Industrial Lighting better than traditional lighting?

LED Industrial Lighting outperforms traditional lighting in terms of energy efficiency, durability, and brightness. It consumes less power, lasts longer, and provides more consistent illumination across large areas.

How long does LED Industrial Lighting typically last?

High-quality LED Industrial Lighting can last up to 50,000 to 100,000 hours, depending on usage and maintenance. This translates to several years of reliable operation with minimal replacement needs.

Can LED Industrial Lighting reduce operational costs?

Yes, LED Industrial Lighting significantly lowers energy bills and reduces maintenance costs. The initial investment is offset by long-term savings, making it one of the most cost-effective solutions for large facilities.

Is LED Industrial Lighting suitable for all types of facilities?

LED Industrial Lighting is highly versatile and can be adapted to warehouses, factories, logistics centers, and even specialized environments like cold storage. Customizable designs make it suitable for nearly any industrial application.

Table of Contents

- The importance of proper LED Industrial Lighting in large-scale environments

- Factors to consider when selecting LED Industrial Lighting

- Design considerations for LED Industrial Lighting

- Installation and maintenance of LED Industrial Lighting

- Benefits of LED Industrial Lighting for large facilities

- Technology advancements in LED Industrial Lighting

- Cost considerations of LED Industrial Lighting

- Customization and adaptability of LED Industrial Lighting

- Sustainability and environmental impact of LED Industrial Lighting

- FAQ